Provides a simplified, economical and trouble free drive system. While belt misalignment is inherent, it is minimal using standard V-belts. The Drive should be aligned with the belt at the mean diameter of the variable pulley and the recommended shaft center distance used as a minimum.

Aluminum Alloy Pulley Face Material

Faces are light weight, corrosion resistant and have a high wearability computability between the belt and face surface. The model 86TBR uses close grain cast iron faces.

Permanently Lubricated Moveable Face Bushingss

High load carrying precisely fit bronze bushings with a specially formulated oil impregnation are used to eliminate most fretting and corrosion problems. For severe corrosion conditions the pulley shaft can be treated to resist the particular corrosion condition.

Torque Sensing Design

Belt tension is regulated to the load requirements. Bushing wear is reduced by the peripheral support of the cam followers. There are no torque carrying keys.

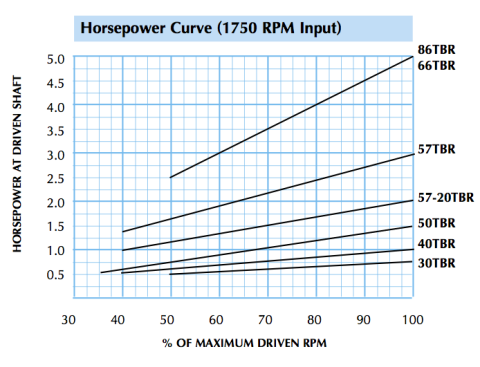

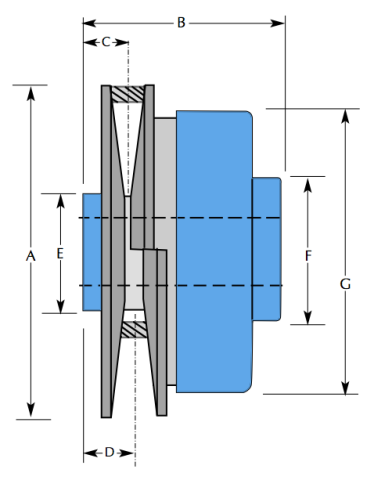

| Model | 1150 RPM HP Rating | 1750 RPM HP Rating | Torque Capacity (lb./In) | Max Pitch Diameter | Min Pitch Diameter | Ratio | Belt Size | A | B | C | D | E | F | G | Stock Thru Bores |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30TBR | 0.75 | 0.5 | 27 | 3.13 | 1.57 | 2:01 | A | 3.38 | 2.69 | 0.78 | 0.97 | 1.69 | 1.88 | 3.06 | .5•.625•.75 |

| 40TBR | 1 | 0.75 | 36 | 4 | 1.6 | 2.5:1 | A | 4.25 | 2.69 | 0.78 | 0.97 | 1.69 | 1.88 | 3.06 | .5•.625•.75 |

| 40TBR-W | 1 | 0.75 | 36 | 4 | 1.125 | 3.4:1 | A | 4.25 | 2.69 | 0.78 | 0.97 | 1.69 | 1.88 | 3.06 | .5•.625 |

| 50TBR | 1.5 | 1 | 54 | 4.65 | 1.72 | 2.7:1 | B | 5 | 3.06 | 0.78 | 1.01 | 2 | 1.88 | 4.06 | .5•.625•.75• .875 |

| 57-20TBR | 2 | 1.5 | 72 | 5.4 | 2.16 | 2.5:1 | B | 5.75 | 3.06 | 0.78 | 1.01 | 2 | 1.88 | 4.06 | .5•.625•.75• .875 |

| 57TBR | 3 | 2 | 108 | 5.4 | 2.16 | 2.5:1 | B | 5.75 | 3.88 | 1.09 | 1.33 | 2.44 | 2.25 | 5.07 | .625•.75•.875•1•1.125 |

| 66TBR | 5 | 3 | 180 | 6.2 | 3.1 | 2:01 | B | 6.63 | 3.88 | 1.09 | 1.33 | 2.31 | 2.25 | 5.07 | .75•.875•1•1.125 |

| 86TBR | 5 | 3 | 180 | 8.28 | 5.17 | 1.6:1 | B | 8.63 | 3.88 | 1.09 | 1.33 | 2.44 | 2.25 | 5.07 | .75•.875•1•1.125 |